St. Mary’s Hospital

Location: Grand Junction, CO

Date Completed: 2016

Construction Cost: $3.5 M

Contact: Nathan Williamson, Project Manager

The Century Tower Project was a game changer for St. Mary’s Hospital in Grand Junction, CO. An expansion and renovation, the project added a new 12-story, 300,000 plus square-foot tower. Four-stories or roughly 120,000 square feet of which were shelled floors. In order to accommodate the expansion St. Mary’s Hospital performed a separate Central Utility Plant (CUP) expansion and tunnel project in advance of the Century Tower project. This project added steam capacity and chiller capacity to the CUP. After just a few short years of operation, St. Mary’s decided it was time to fit-out the remaining four shelled floors. However, additional chiller plant capacity was deemed necessary to establish firm redundancy, and the existing free cooling systems that were not augmented as part of the previous CUP expansion were no longer functional during winter operation due to sizing disparity relative to new building loads. Facilities Engineering had not been able to run the free cooling equipment for over two years.

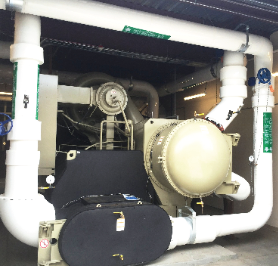

The existing plant consisted of (2) 1300 Ton chillers and (2) 350 Ton chillers for a firm capacity of 2000 Tons which was roughly equivalent to existing building load prior to fit out of the remaining 120,000 square feet of shell space. Without an augmentation, the full build out would have overloaded the plant in the event of failure of either of the 1300 Ton chillers. Furthermore, the two smaller 350 Ton chillers were fed from the Emergency Power system to provide continuity of cooling service to critical loads (ICU, NICU, etc.) during loss of Normal Power, but these chillers were served by two fiberglass cooling towers that had reached the end of service life.

At the onset of design for upgrades required to support the upcoming Century Tower completion project the Owner had defined minimum scope required. For work at the plant, scope included addition of a single chiller and cooling tower only without consideration toward any investment in the aged cooling towers or the undersized free cooling equipment. Despite project budget limitations, Lead HVAC technician David Maloney pleaded “just give me a bridge to somewhere…” in reference to upcoming work and planning that would allow for future correction of those items.

In response to that request, Project Manager Todd Spacek and Lead Mechanical Jake Blevins devised a comprehensive plant upgrade to update the aged cooling towers, augment plant capacity to provide a firm capacity meeting summer cooling loads, and restore functionality to the existing free cooling assets. Though project budget did not support all items, a phased approach allowed the complete plant upgrade to be completed in conjunction with later bed floor build out budget allocations.

The crux move for the project was the free cooling component. After the large Century Tower addition, the existing Plate & Frame heat exchanger was no longer large enough to meet winter chilled water loads. Furthermore, the existing piping configuration did not allow for integrated water-side economizer mode meaning that only free cooling or mechanical cooling modes (chiller operation) were possible. In addition to adding 1300 Tons of chiller capacity for a total plant, Todd & Jake devised a scheme to replace the aged emergency cooling towers with updated units dedicated to free cooling operation. The point of connection for the free cooling system was modified to achieve series flow relationship to chillers and new towers were established as dedicated to the free cooling equipment.

Energy efficiency measures including high efficiency chiller, dedicated flat plate free cooling, and primary/secondary flow matching were submitted to the Utility Provider, Xcel Energy. A rebate in excess of $200,000 was offered by Xcel as part of their custom rebate incentive program.

After more than three years in the making and phasing to comply with available capital, the Plant Upgrade project was completed. In March of 2016, the flat plate water-side economizer was placed into full operation. For the first time in more than 50 years, the central plant supported the entire hospital’s chilled water demand without the use of chillers and energy intensity has been substantially reduced. Due to the significant energy savings associated with free cooling operation, return on investment for these measures is estimated to be less than 3 years. Also, useful service life of the existing chiller assets is significantly lengthened due to reduced run times.